|

The journey begins with the creative minds at Mass Polishing conceptualizing and refining the mechanical design of our mass-finishing machines. Through years of expertise and industry knowledge, our engineers meticulously craft designs that optimize functionality, durability, and efficiency.

|

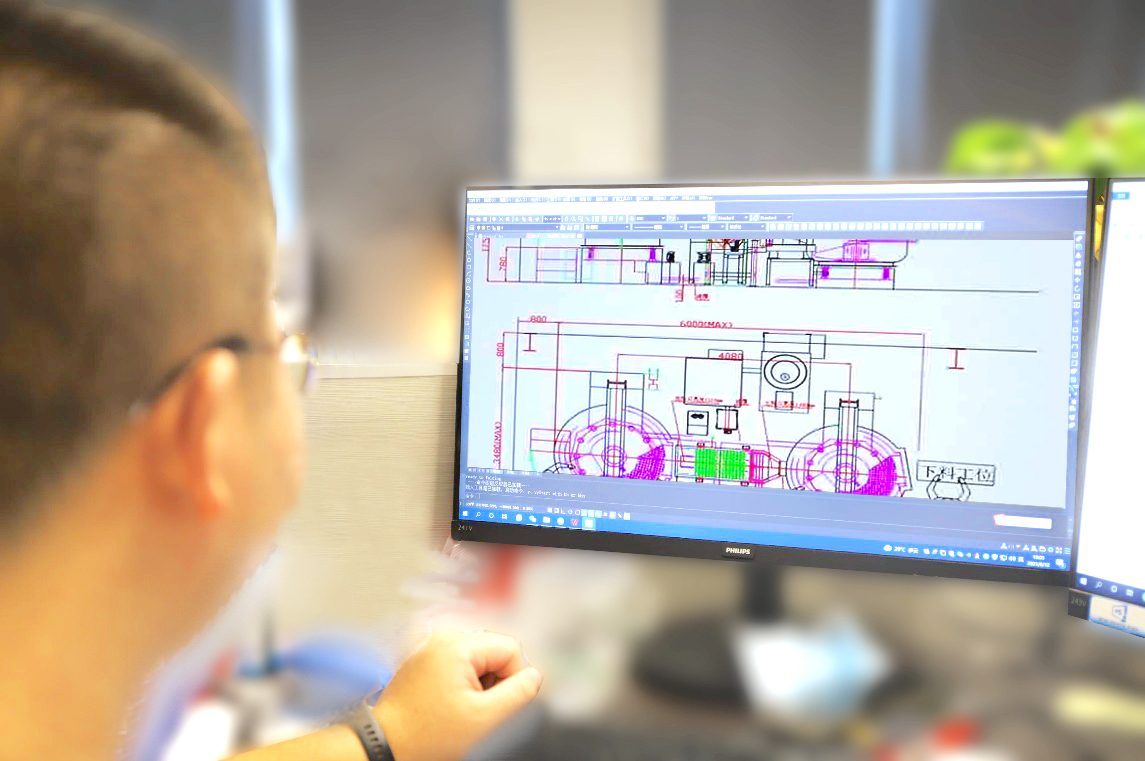

Once the mechanical design is finalized, Mass Polishing's team of skilled CAD designers transforms the concept into precise and detailed 3D computer-aided design (CAD) drawings. These drawings serve as the blueprint for every component, ensuring accurate manufacturing and assembly processes.

|

With the CAD drawings in hand, the manufacturing process shifts gears to Mass Polishing's state-of-the-art CNC (Computer Numerical Control) machining center. This cutting-edge technology enables the precise fabrication of intricate parts and components with unparalleled accuracy, consistency, and repeatability.

|