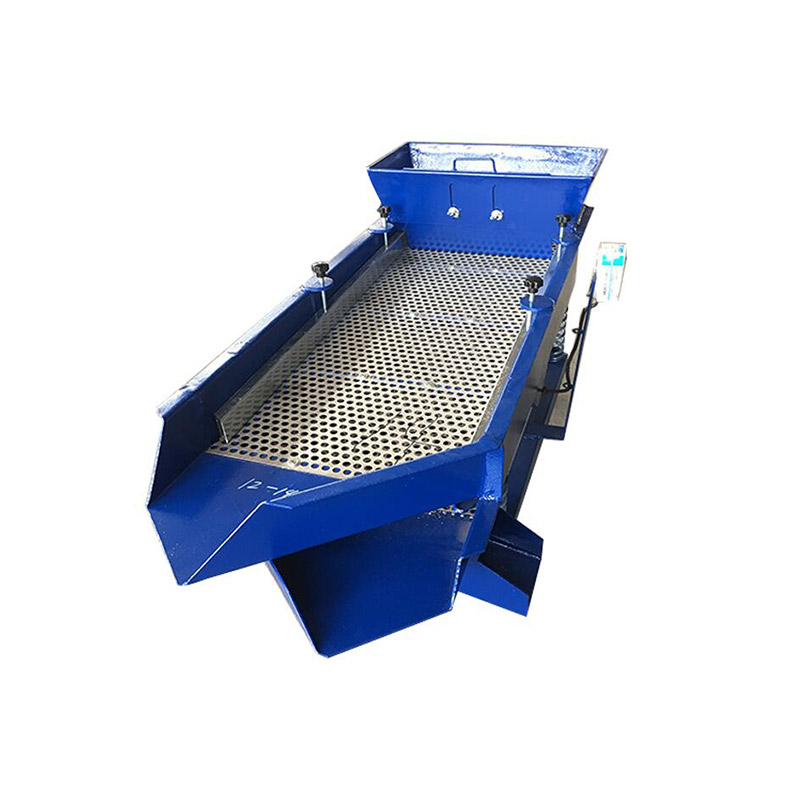

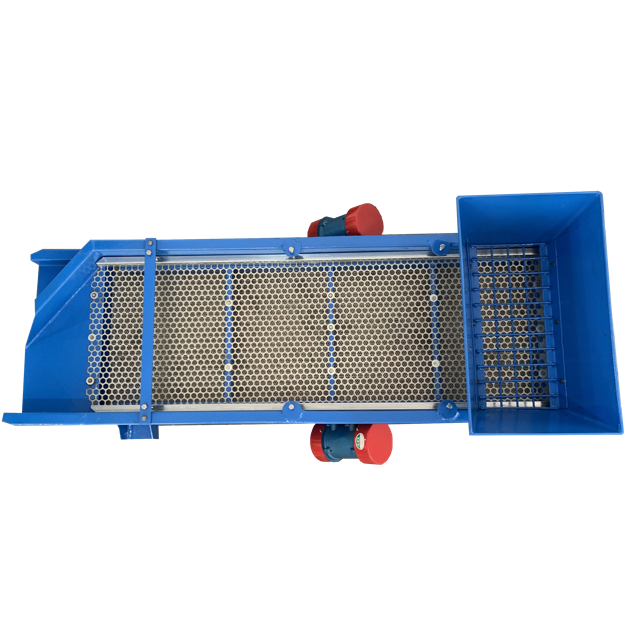

There are several reasons why investing in your own media separators can be a good idea:

Increased Efficiency:

By using a media separator, the time and effort required to separate the media from the parts can be greatly reduced, leading to increased efficiency and improved productivity.

Improved Quality:

The use of a media separator can result in improved quality of the processed parts, as it can more effectively remove debris and ensure that the desired finish is achieved.

Cost Savings:

Over time, the use of a media separator can result in cost savings, as it can reduce the amount of media that is wasted and reduce the amount of time and effort required to process parts.

Improved Safety:

By using a media separator, the risk of injury from manual media separation can be reduced, as the separator automates the process.

Increased Control:

By using a media separator, it is possible to have greater control over the processing parameters, such as speed and vibration, to achieve the desired results.

Customizable:

Many media separators can be customized to meet specific requirements, such as the size and shape of the parts to be processed, making them a versatile investment.

Welcome to contact us for investing in your ideal media separators today!