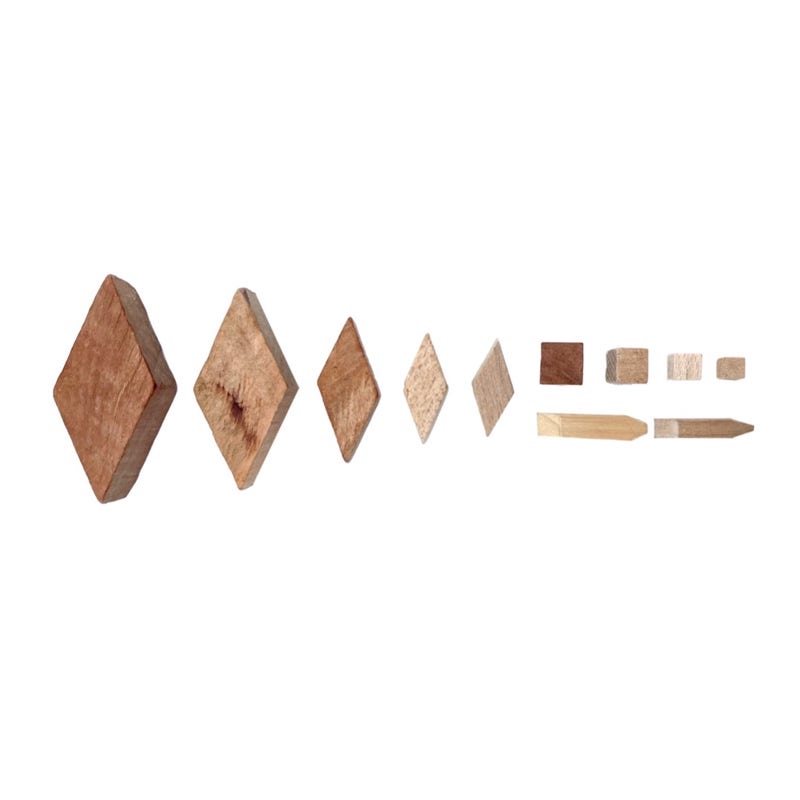

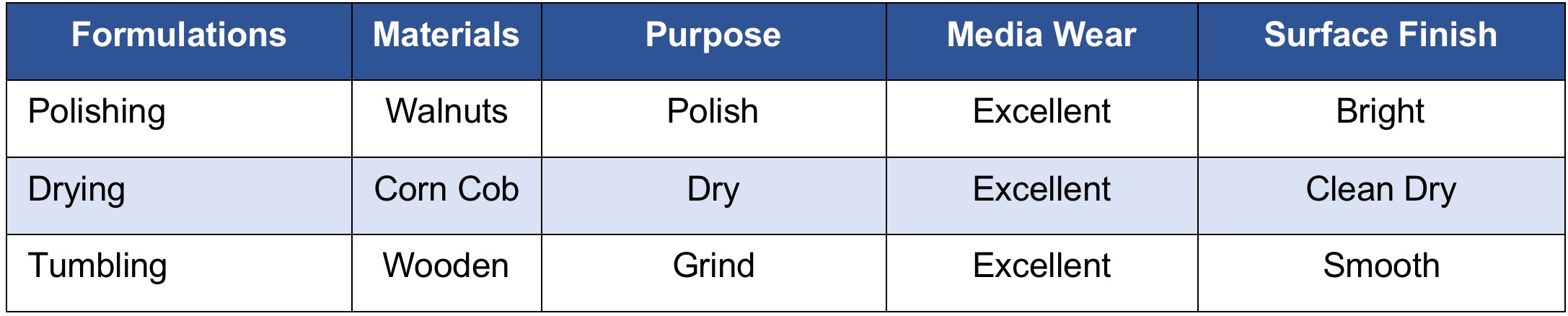

Dry finishing media is an abrasive material used in mass finishing processes to create a smooth and uniform surface on workpieces. This versatile solution is available in various shapes, sizes, and abrasiveness levels, making it suitable for various applications. Dry finishing media is efficient, cost-effective, and customizable, making it a popular choice for many industries.

In conclusion, dry finishing media is a valuable investment for any manufacturing process that requires a smooth and uniform surface finish. Its versatility, range of abrasiveness levels, and consistent results make it a preferred solution for industries such as automotive, aerospace, and manufacturing.