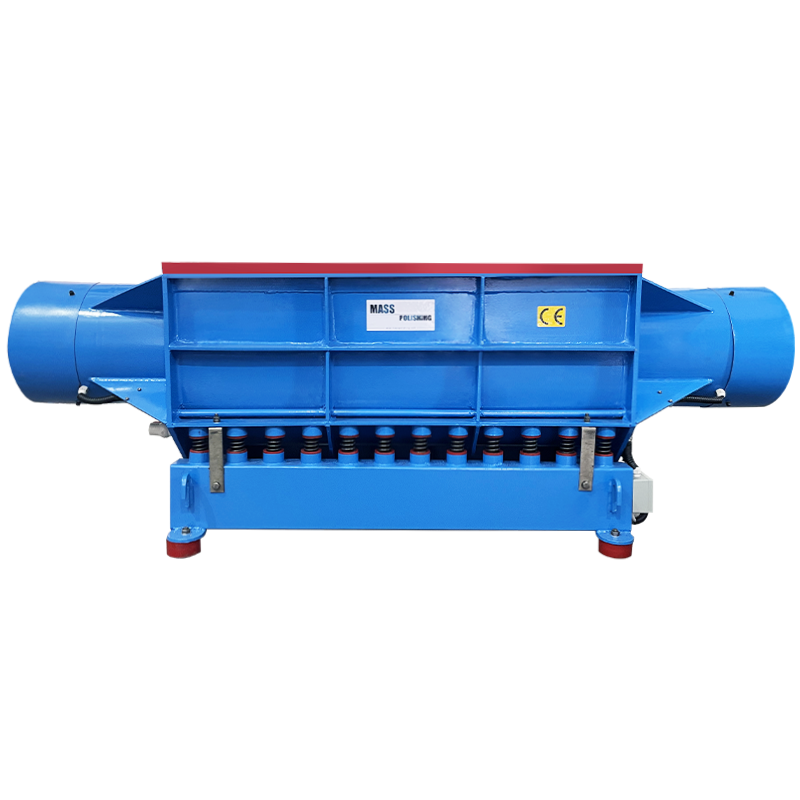

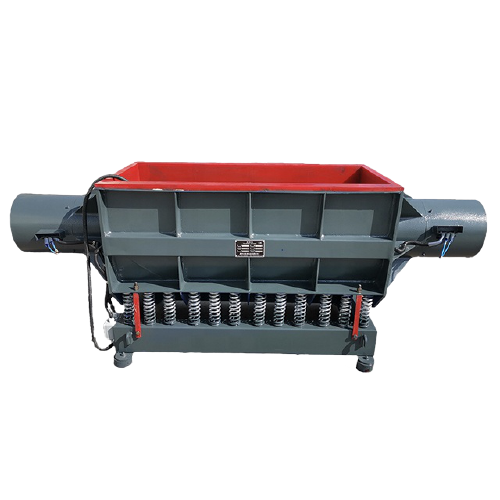

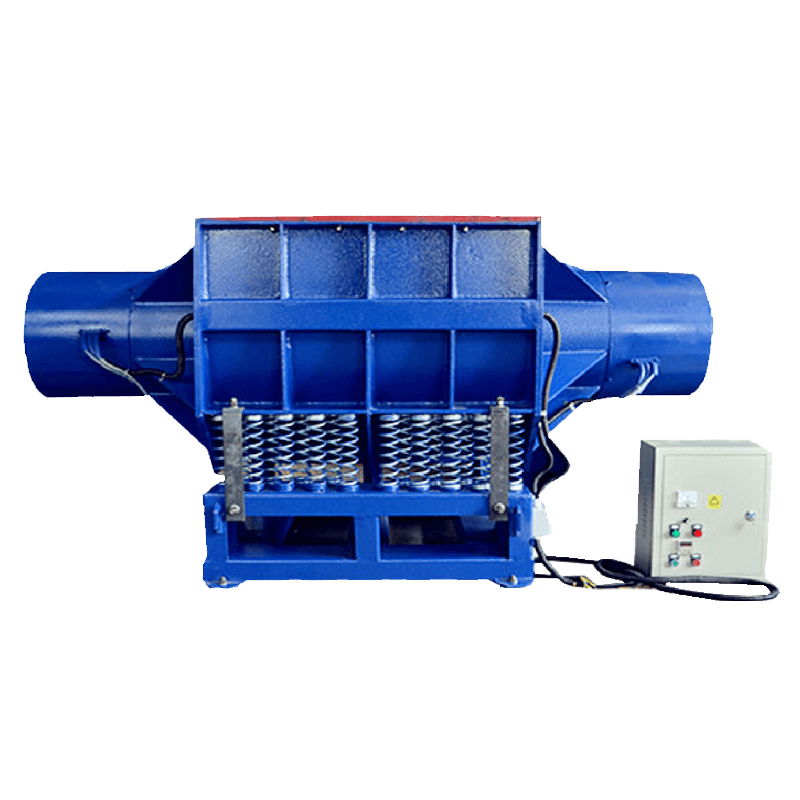

A Vibratory Tub Finishing machine is a type of mass finishing equipment that uses vibration and media to deburr, smooth, and polish metal parts. The machine consists of a tub-shaped work chamber, a drive system to generate the vibratory motion, and a media/parts charge.

The process of using a Vibratory Tub Finishing machine is simple: parts and an appropriate media are placed in the work chamber and the drive system generates the vibratory motion. This agitates the parts and media, which interact with each other in order to provide a finishing action on the parts.

Vibratory Tub Finishing machines are an efficient and cost-effective way to finish a wide range of metal parts in mass finishing applications, such as automotive, aerospace, medical devices, industrial manufacturing, and metal fabrication.