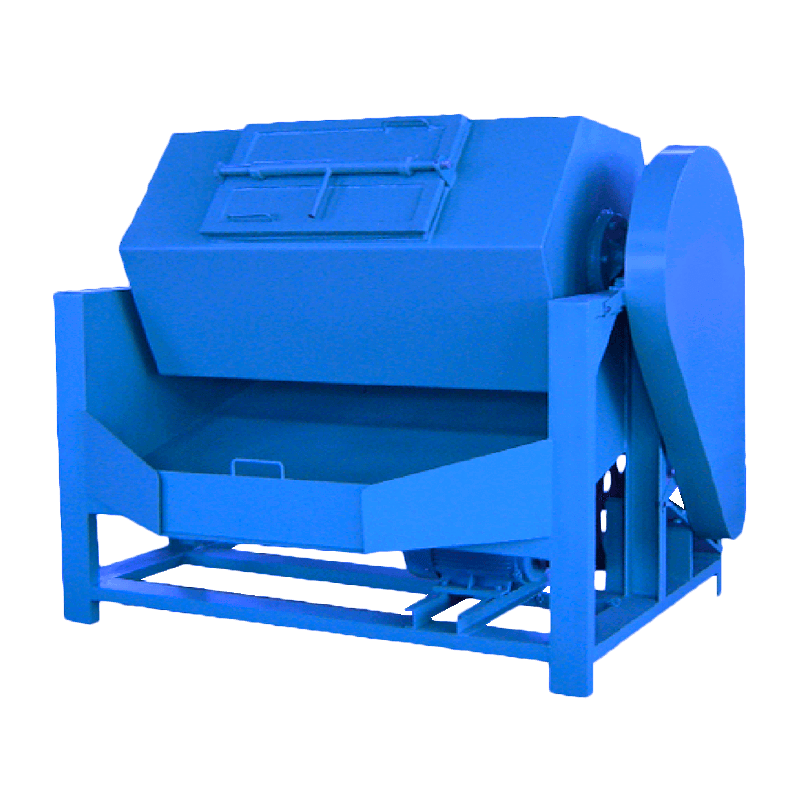

A rotary barrel tumbling machine is a machine that is used to polish, deburr, or clean small parts or components by placing them in a barrel along with abrasive media and rotating the barrel. The abrasive media, such as sand, ceramic beads, or steel shot, rubs against the parts or components as the barrel rotates, removing burrs, polishing surfaces, and cleaning off any contaminants.

The barrel is typically lined with rubber or similar material to reduce noise and wear on the parts or components. The tumbling process can be adjusted by varying the speed of the barrel rotation, the type and amount of abrasive media used, and the duration of the tumbling process.

Rotary barrel tumbling machines are used for large quantities of parts or components and have several benefits in the industry such as efficiency, consistency, versatility, cost-effectiveness, and safety, in different applications like deburring, polishing, cleaning, and surface preparation.