3P Granule Finishing Media is a powerful tool for businesses looking to improve the surface finish of their parts and components. This specialized type of abrasive media is designed for high-speed finishing processes and is ideal for use with a variety of materials, including metals, plastics, and ceramics. The granular shape of 3P Granule Finishing Media allows it to easily conform to the contours of the part, providing an even and consistent finish. Additionally, the unique blend of materials used in 3P Granule Finishing Media makes it extremely durable and long-lasting, making it an excellent choice for high-volume finishing applications.

One of the key benefits of 3P Granule Finishing Media is its ability to provide a smooth and uniform surface finish, even on complex shapes. Its granular shape also makes it ideal for removing heavy burrs, rust, and other imperfections, making it an effective choice for a variety of surface preparation and finishing tasks. Additionally, 3P Granule Finishing Media is safe to use and does not produce harmful dust or debris, making it an ideal choice for applications in a variety of industries, including automotive, aerospace, and medical.

Whether you are looking to improve the surface finish of your parts, increase efficiency, or enhance the durability of your finished products, 3P Granule Finishing Media is an excellent choice. So why wait? Invest in the power of 3P today and see the difference for yourself.

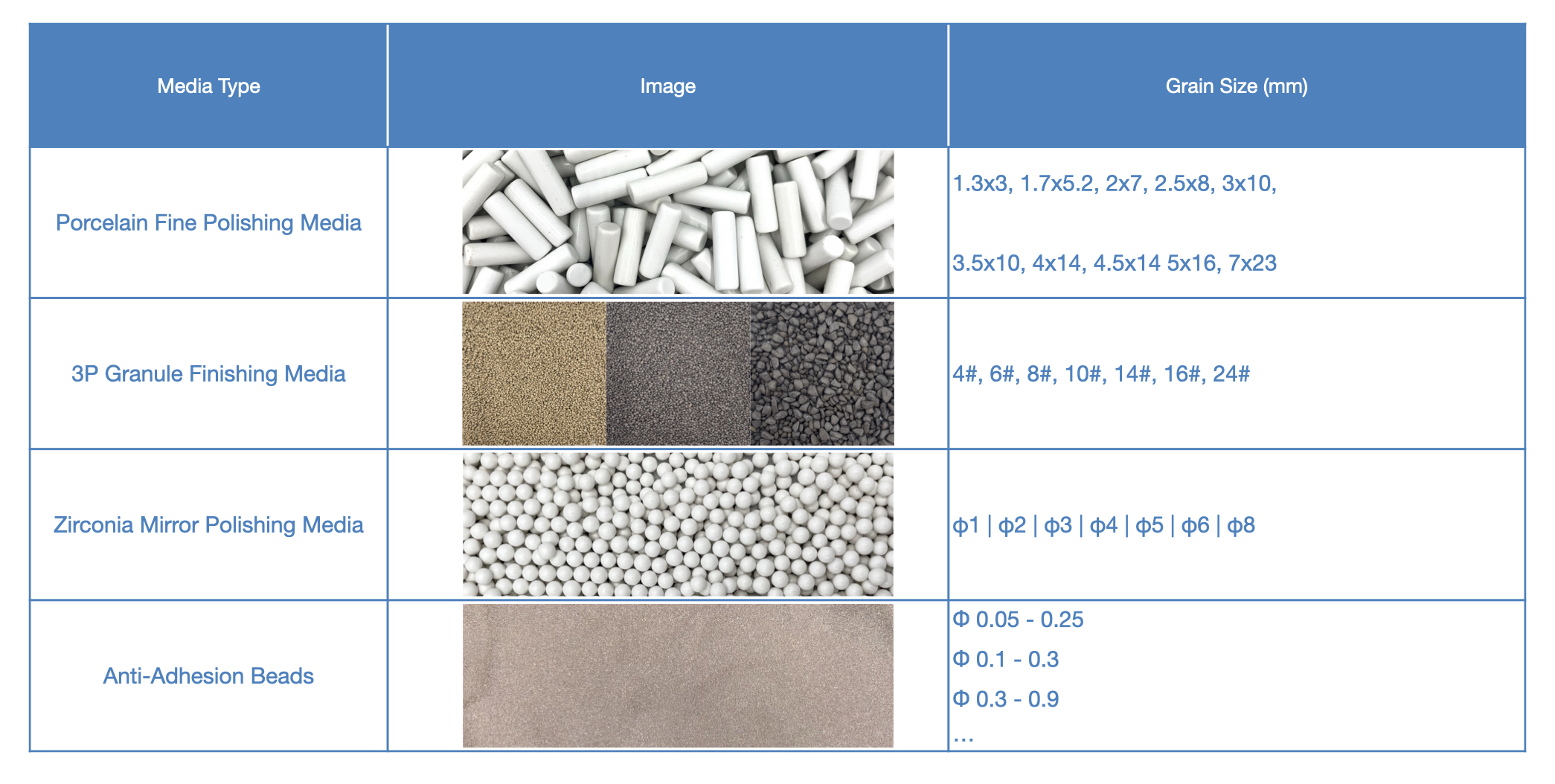

3P Granule Finishing Media Data