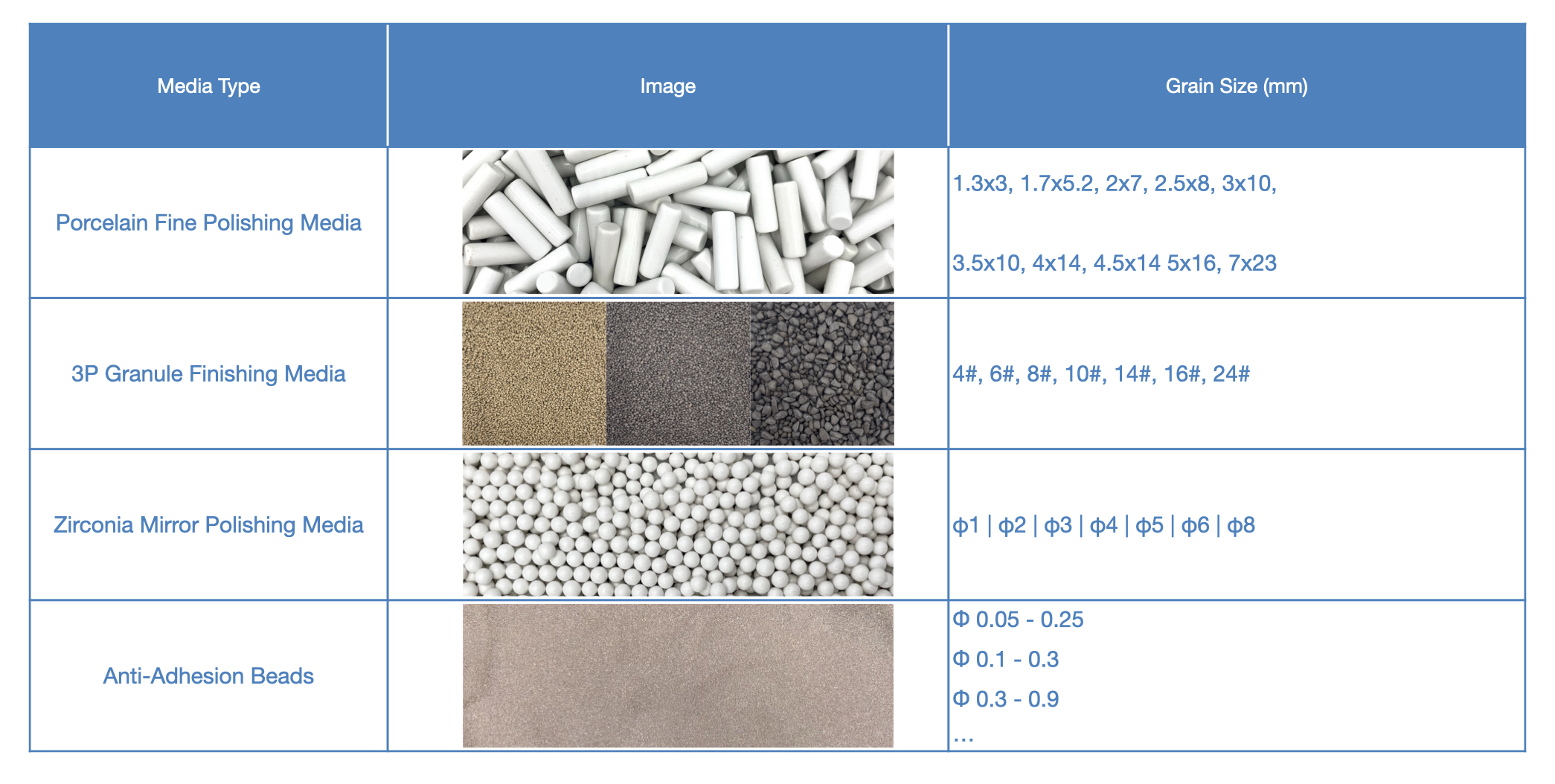

Special finishing media has a wide range of applications in various industries due to its ability to improve the surface finish of parts and components. Here are some common applications of special finishing media:

Automotive Industry - Special finishing media is used in the automotive industry to achieve a high-quality finish on parts such as engine components, wheels, and exterior body parts.

Aerospace Industry - In the aerospace industry, special finishing media is used to finish parts for aircraft, including engine components, landing gear, and structural components.

Electronics Industry - The electronics industry uses special finishing media to improve the surface finish on components such as circuit boards, display screens, and electronic components.

Medical Industry - In the medical industry, special finishing media is used to finish parts for medical devices, such as surgical instruments, dental implants, and orthopedic implants.

Jewelry Industry - The jewelry industry uses special finishing media to improve the surface finish on precious metal and gemstone jewelry, achieving a high level of gloss and reflection.

Cosmetic Industry - The cosmetic industry uses special finishing media to finish containers and packaging for cosmetic products, achieving a high level of gloss and smoothness.

Chemical Industry - In the chemical industry, special finishing media is used to finish parts for chemical processing equipment, such as pumps, valves, and pipelines, preventing the buildup and adhesion of foreign materials.

Food and Beverage Industry - The food and beverage industry uses special finishing media to finish parts for food processing and packaging equipment, such as conveyors and bottling machines, preventing contamination and buildup.

These are just a few of the many industries that use special finishing media in their processes. The wide range of applications is due to the versatility and benefits that special finishing media can provide, including improved surface finish, increased durability, enhanced functionality, increased efficiency, and cost savings.