|

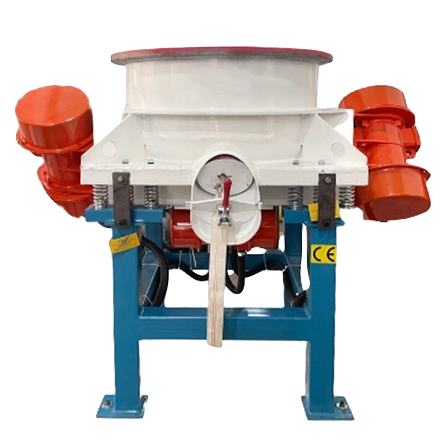

Mechanical Design: The journey begins with the creative minds at Mass Polishing conceptualizing and refining the mechanical design of their vibratory wheel polishing machines. Through years of expertise and industry knowledge, their engineers meticulously craft designs that optimize functionality, durability, and efficiency.

|

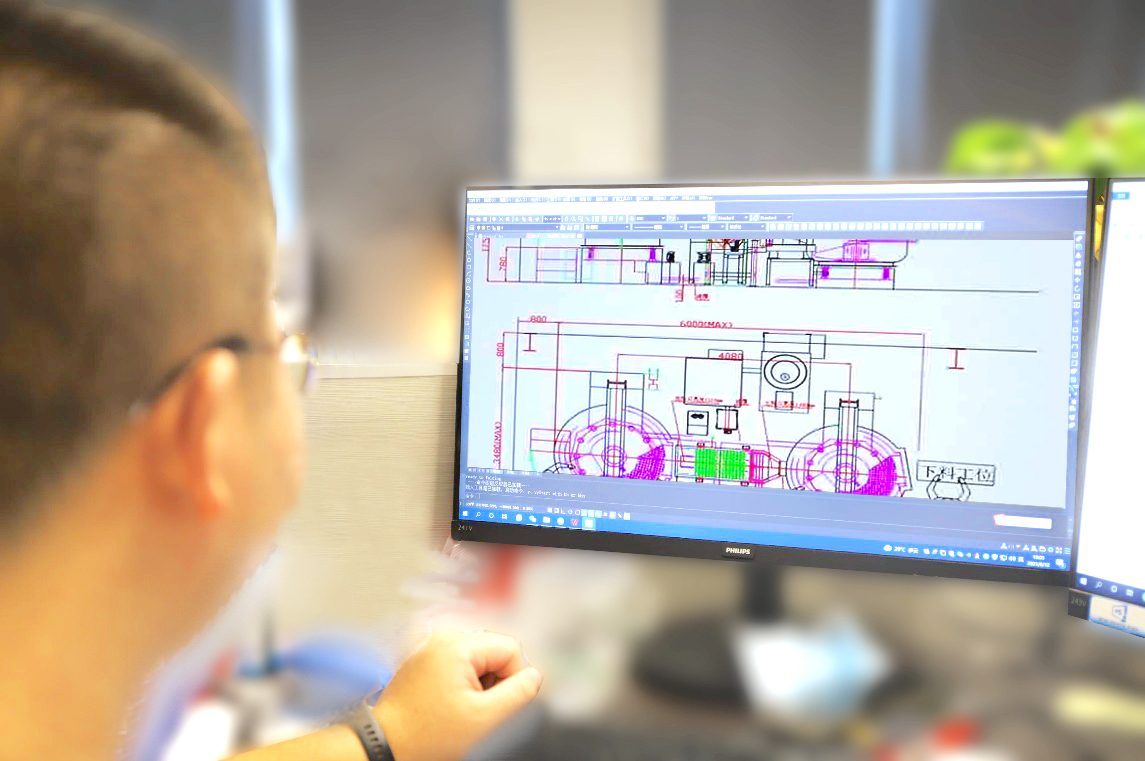

CAD Drawing Planning: Once the mechanical design is finalized, Mass Polishing's team of skilled CAD designers transforms the concept into precise and detailed 3D computer-aided design (CAD) drawings. These drawings serve as the blueprint for every component, ensuring accurate manufacturing and assembly processes.

|

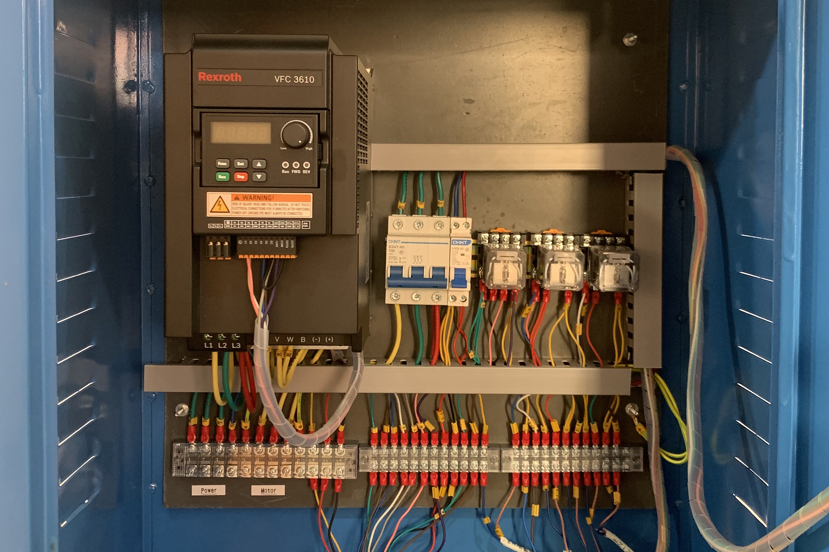

CNC Machining: With the CAD drawings in hand, the manufacturing process shifts gears to Mass Polishing's state-of-the-art CNC (Computer Numerical Control) machining center. This cutting-edge technology enables the precise fabrication of intricate parts and components with unparalleled accuracy, consistency, and repeatability.

|