|

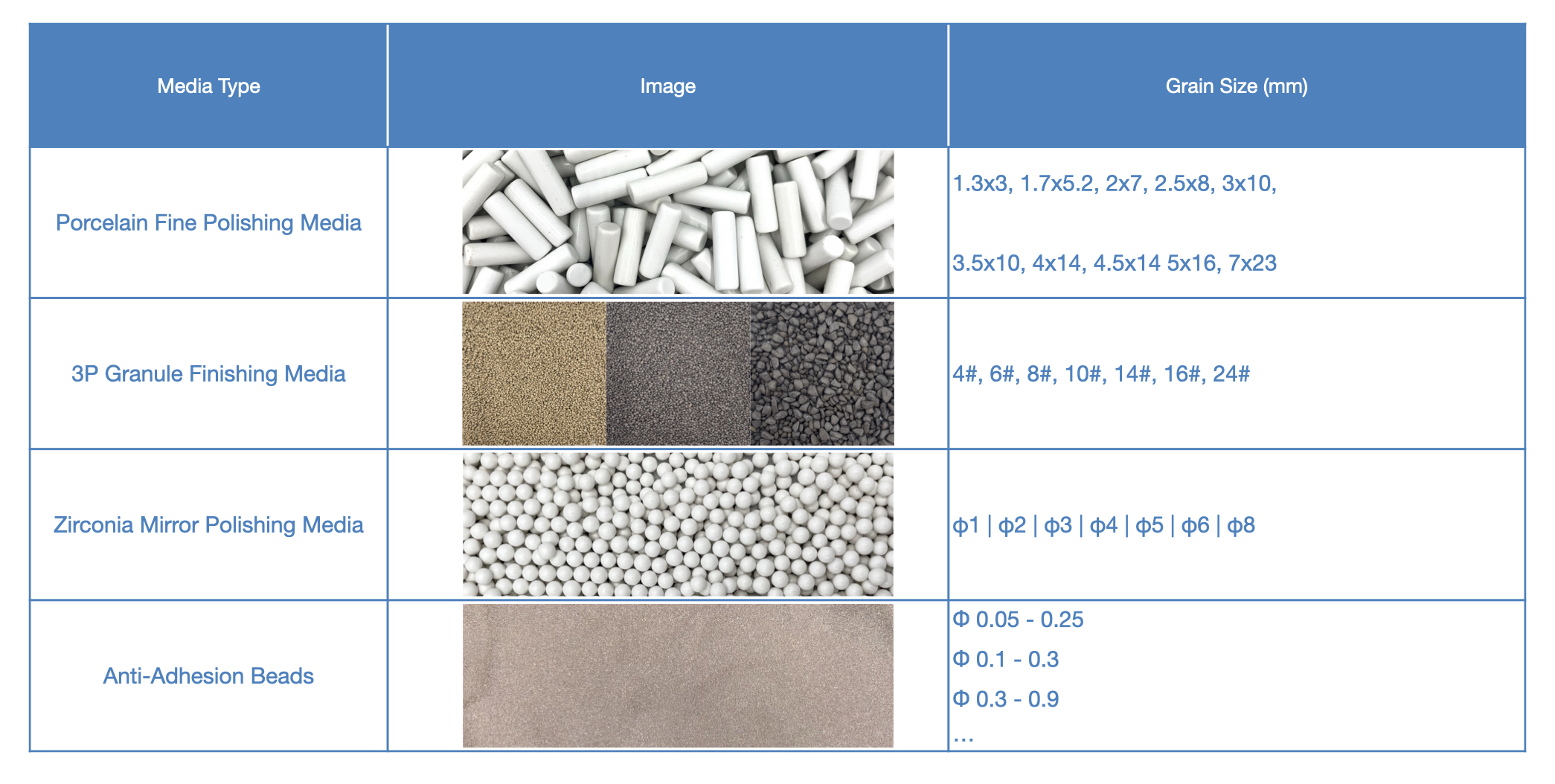

Our production process begins with meticulous material selection. We carefully choose the finest ceramic and porcelain materials known for their hardness and abrasive properties. This ensures that our tumbling media delivers optimal performance and durability, enabling efficient deburring, polishing, and surface finishing.

|

First, the selected ceramic material is mixed with water and specialized additives to form a slurry. This slurry is then shaped into various geometries, including cylinders, triangles, and cones, through molding or extrusion processes. Our skilled technicians ensure the consistency and precision of each piece.

|

After shaping, the ceramic pieces undergo natural drying. We utilize the power of air circulation and controlled environments to allow the moisture to gradually evaporate from the ceramic. This natural drying process ensures that the ceramic pieces solidify and maintain their intended shape without the need for additional heat sources.

|