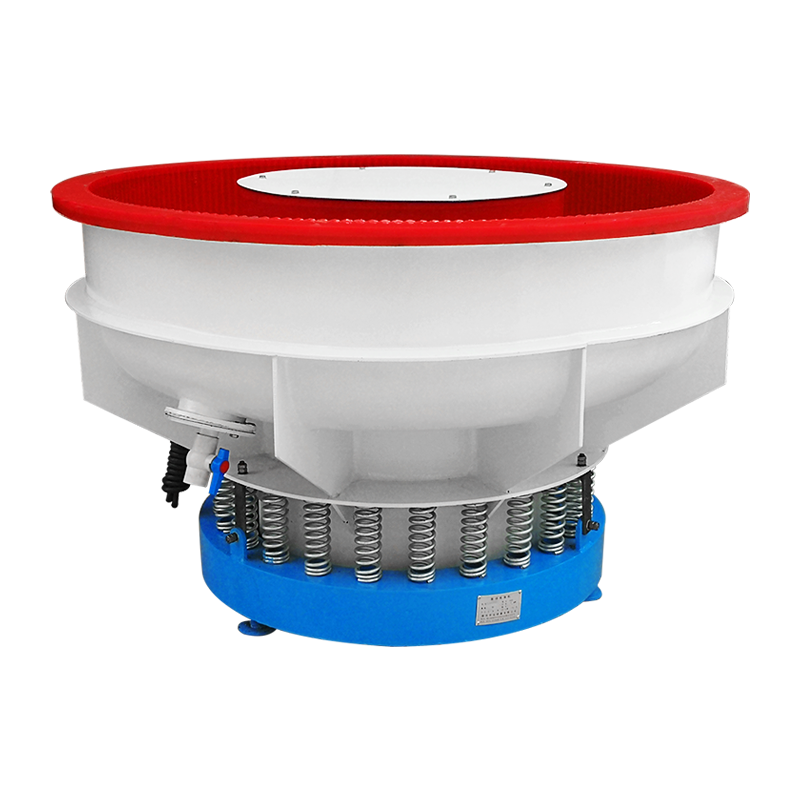

Vibration grinder is a kind of grinding surface treatment, deburring, deburring, degreasing, de-spotting, vibration treatment, etc. on the surface of hardware workpieces, so that the workpiece is closely and evenly mixed with grinding stones or steel balls, abrasives, etc. , Rolling in a spiral vortex shape to grind and cut or polish the surface of the work object, especially those that are susceptible to deformation or complex shapes, and the dead corners in the hole can be ground with this machine to obtain uniform cutting quality, and it can be cut during processing. Sampling tests at any time to save time and improve quality.

Many customers want to improve the grinding efficiency during the grinding process to achieve high-efficiency production. In fact, the following points can achieve the method to improve the grinding efficiency of the vibration grinder.

1. Choose the right grinding stone according to the material of the workpiece:

The commonly used grinding stones for grinding and polishing include rough grinding stones, medium grinding stones, polishing stones, steel balls, etc. If you need to remove burrs and draping on the surface of the product, you can choose brown corundum grinding stones and plastic grinding stones. Grinding stones are generally divided into numbers (the roughness of the grinding stones), the larger the roughness = the lower the mesh number = the stronger the cutting force, the smaller the roughness = the higher the mesh number = the weaker the cutting force, so the grinding efficiency of the workpiece That is to say, there is a certain effect. The grinding stone will be worn out according to the grinding product and time, and it needs to be replaced or added with new grinding stones regularly to achieve the grinding effect of the product.

2.brightener, polishing liquid:

Vibration grinder needs to add brightener or grinding fluid in the grinding process to cooperate with the grinding stone to have the effect of lubrication and cleaning, and effectively achieve the effect of grinding brighter and faster. The grinding fluid of Xinyuan Yuyan includes lubrication , Cooling, anti-rust performance, cleaning and other multi-effect grinding fluid, can achieve satisfactory grinding effect of workpiece faster.

3. Grinding equipment:

Choose a suitable vibration grinder according to the workpiece to meet the capacity requirements of the workpiece, and perform standardized operations according to the operation mode of the grinder. Xinyuan Yuyan’s fully automatic discharging vibration grinder can automatically output after the grinding is completed. It saves operating time greatly. The fully automatic eddy current finishing machine adopts PLC program program operation control, and the whole process is automated one-key operation to improve efficiency, save costs, and reduce operating labor.