Vibration grinders are used in bicycles, aluminum die castings, zinc die castings, furniture hardware, clothing hardware, luggage hardware, glasses accessories, wall clock accessories, locks, electronic accessories, all kinds of jewelry, jewelry and powder metallurgy, resin, etc. For stainless steel, iron, copper, zinc alloy, aluminum alloy, magnesium alloy and other raw materials through stamping, die casting, casting, casting, for wire, ceramics, jade, coral, synthetic resin, plastic, porcelain and other raw material workpiece surface polishing, pouring Angle, in order to meet the requirements of deburring, rust removal, rough polishing, fine polishing, gloss polishing and so on.

Vibration grinding machine is suitable for surface polishing, chamfering, deburring, polishing, and gloss polishing of small and medium-sized workpieces. Surface finish and precision.

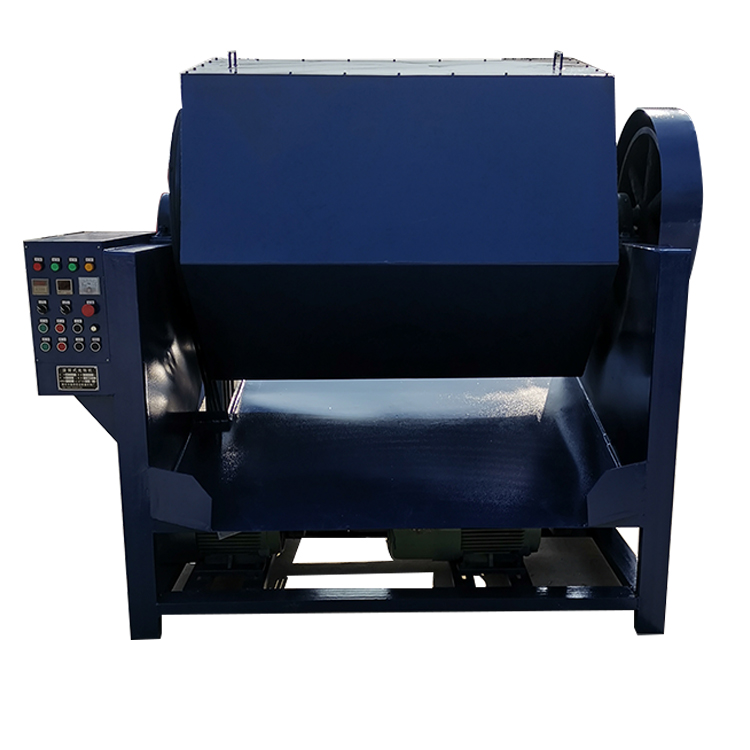

Equipment features:

1. It can grind many workpieces at one time, check the processing status of parts at any time, automatic and unmanned operation, simple and convenient operation, one person can operate multiple machines, which greatly improves the work efficiency and saves the cost of the enterprise.

2. The inner lining rubber is divided into polyurethane PU rubber and rubber. The wear resistance of polyurethane is 3-5 times that of rubber, the thickness is 8-15mm, and the service life is longer.

3. The spiral tumbling activity and the three-dimensional vibration principle are used to make the parts and the tumbling abrasive grind each other.

4. The processing process does not destroy the original size, shape, and surface accuracy of the parts.

Advantages of vibrating grinder:

1. The world's advanced spiral tumbling activity and the principle of three-dimensional vibration are used to make the parts and the grinding stone grind each other, and then remove the burrs, oxide skin and oil stains on the surface of the workpiece. Different grinding stones and grinding aids can be selected according to the difference of workpiece raw materials and shapes, which can greatly improve the smoothness and brightness of the workpiece surface.

2. It is suitable for polishing and grinding of large quantities of small and medium-sized parts, improving work efficiency by 6-10 times.

3. The processing process does not destroy the original size and shape of the parts.

4. The vibration grinding machine can complete automatic and unmanned operations, and the operation is convenient. During the work process, the processing status of the parts can be checked at any time.